Private customers

If you want to have your motorcycle, scooter, MP3 or bicycle or e-bike measured, you will find below the map with our contractors

Commercial customers

If you are interested in commercial use, an overview of our measuring systems is available here

We at Scheibner m-tec GmbH have been producing and selling mobile measuring systems for motorcycle frames and chassis for over 30 years. You get detailed results on the condition of the vehicle geometry.

Under ›Information‹ you will find an overview of all the important questions, why measurement is necessary and what the advantages of Scheibner measuring systems are

What is important to us

Customer service

We are there for you and provide a database with the characteristics of over 1,800 vehicle models

Good results

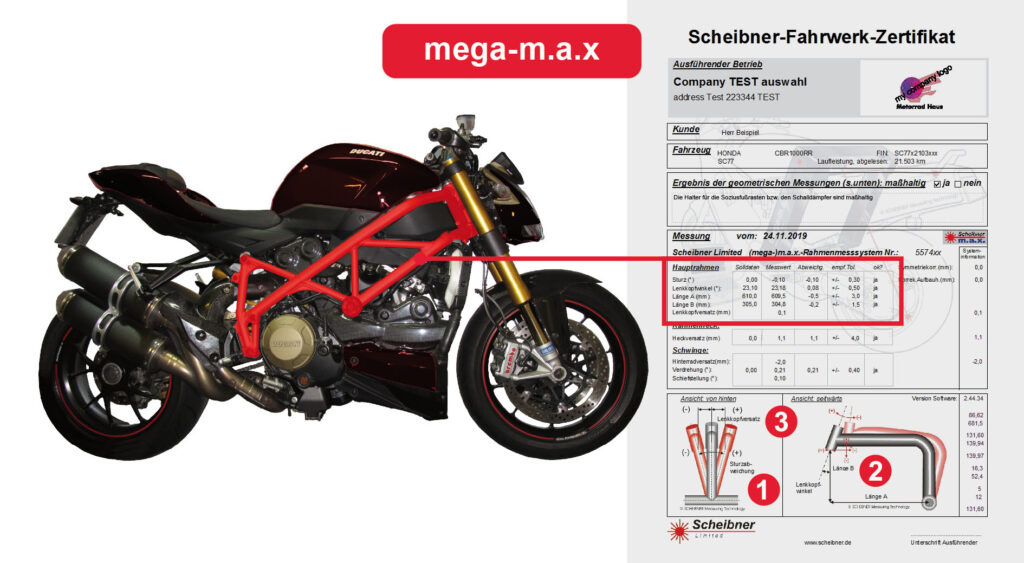

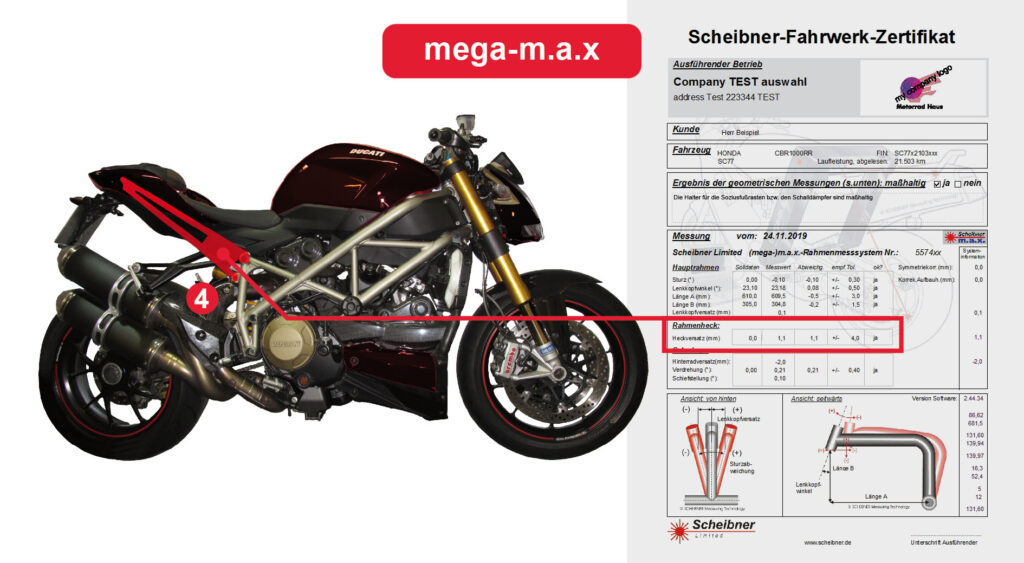

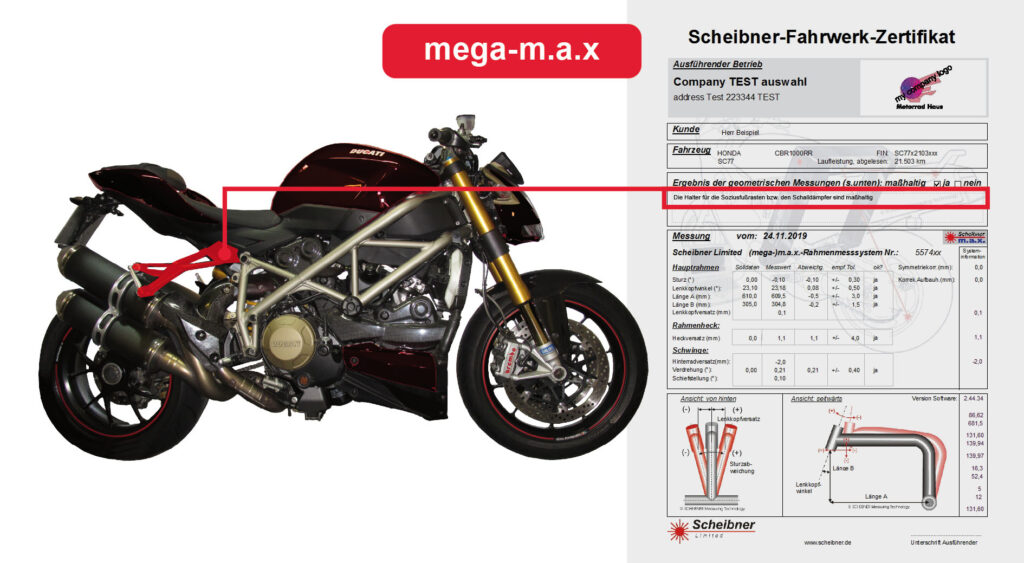

We are working on standards for meaningful measurement protocols, such as the ›Scheibner-Chassis-Certificate‹

Collaboration

We are convinced that the best ideas are created within a community – which is why we work with hundreds of contract partners worldwide

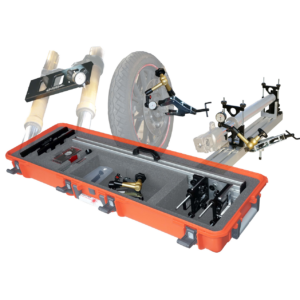

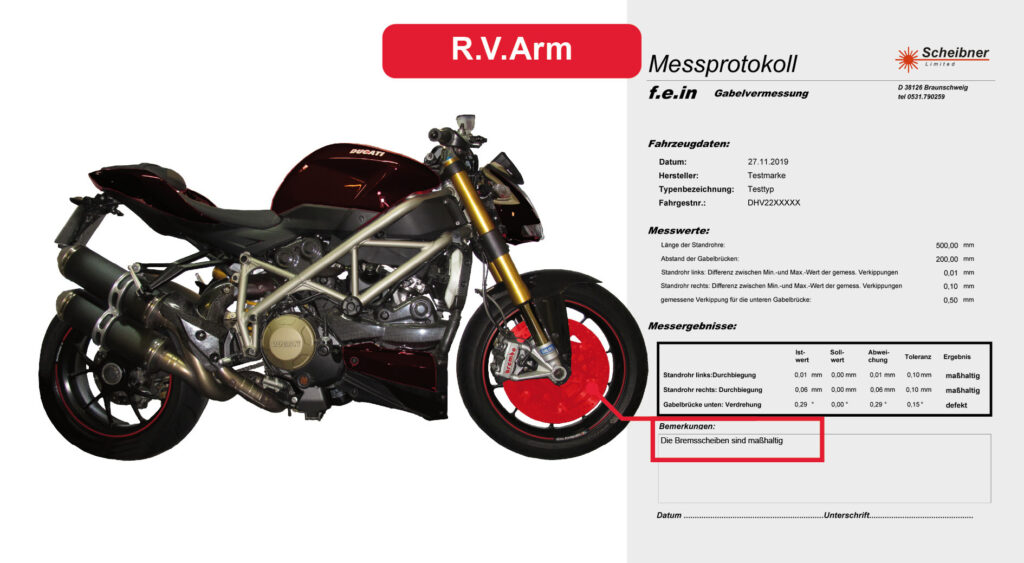

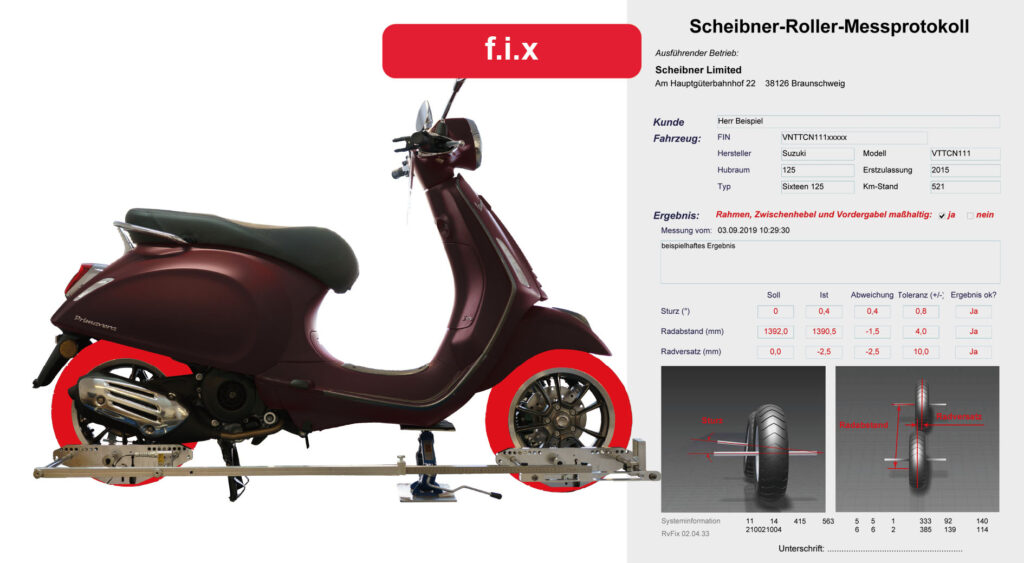

Various measuring systems, suitably developed for clarifying the geometric condition of frames and other chassis parts, e.g. after an accident

- All

- Motorcycle

- Bicycle

- Scooter & MP3

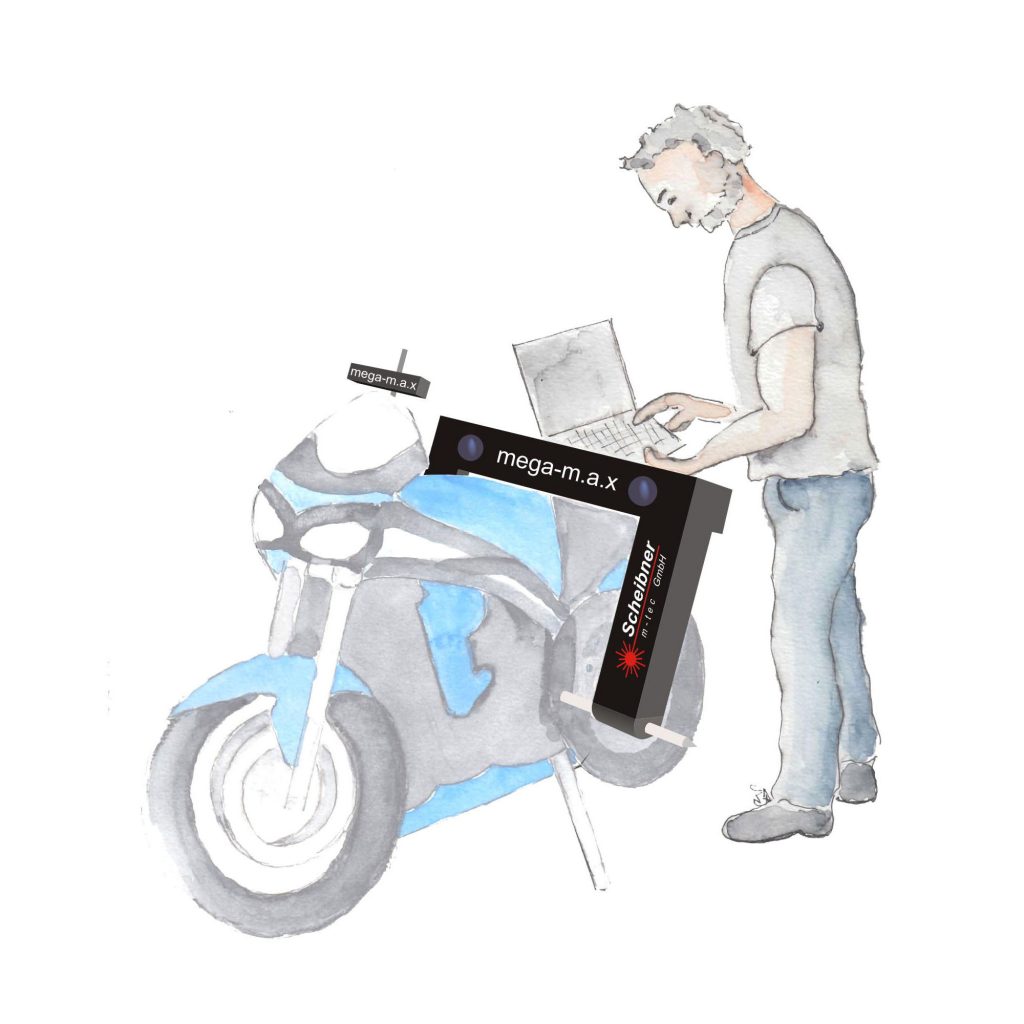

mega-m.a.x

Frame/chassis, Motorcycle Play Video The mega m.a.x is our standard measuring system for motorcycles and determines the…

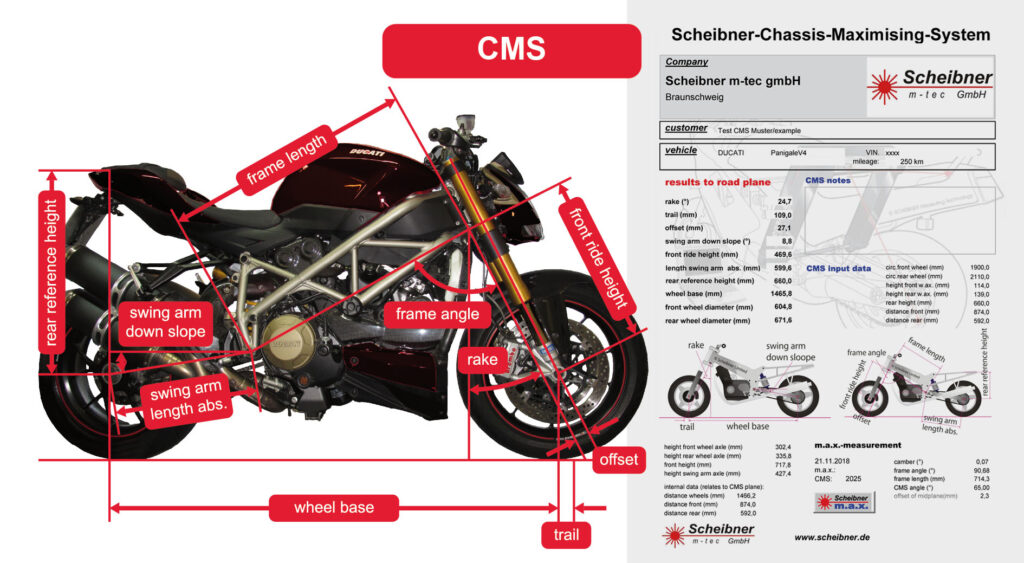

CMS

Frame/chassis, Motor racing, Motorcycle The CMS (Chassis Maximizing System) is the optional extension of the mega-m.a.x for…

Feinbank-System

Front end/Front, Motorcycle The Feinbank-System is used for the exact measurement of the relevant components of the…

Fahrfix

Fahrrad Um E‐Bikes, Fahrräder und Ähnliche zu vermessen, haben wir das laser-basierte Fahrfix-System entwickelt. Es eignet sich…

What our measuring systems measure and what the results in the protocols look like

1 The camber deviation of a single-track vehicle or two-wheeler describes the position of the steering head axis relative to the swinging arm axis, with regards to distortion around the longitudinal axis of the vehicle

2 Steering head angle and length A and B provide the information displayed at the image. Please note that the steering head angle of the frame does not necessarily correspond with the rake or steering head angle of the complete motorcycle on the road such as mentioned in brochures.

3 The longitudinal axis setting is a measurement of the offset of the steering head axis relative to the midplane of the motorcycle. Please note that this value solely provides information for the expert and is, on its own, not relevant in the case of an accident.

4 The tail offset is the sideways offset of the frame rear to the midplane

5 Rear wheel offset is the sideways offset of the rear wheel to the midplane

6 Distortion of the swing arm is the distortion of the rear wheel axis relative to the swing arm axis from the rear view

7 Misalignment of the swing arm is the distortion of the rear wheel axis relative to the swing arm axis as viewed from above (problems are related in most cases to chain adjustment and not accident-related)

Partner

Find one of our partners in your region here.