Wenn sie ihr Motorrad, ihren Roller, MP3 oder ihr Fahrrad bzw. E-Bike vermessen lassen wollen, finden sie unten die Karte mit unseren Vertragspartnern

Wenn sie sich für die gewerbliche Nutzung interessieren, finden sie hier die Übersicht über unsere Messsysteme

Wir von der Scheibner m-tec GmbH produzieren und vertreiben seit über 30 Jahren mobile Messsysteme für Rahmen und Fahrwerke von Motorrädern. Sie erhalten detaillierte Ergebnisse zum Zustand der Fahrzeuggeometrie.

Einen Überblick über alle wichtigen Fragen, warum gemessen werden sollte und was die Vorteile der Scheibner Messsysteme sind, finden sie unter ›Informationen‹

Was uns wichtig ist

Kundenservice

Wir sind für sie da und stellen u.a. eine Datenbank mit den Kenndaten von über 1.800 Fahrzeugmodellen

Gute Messergebnisse

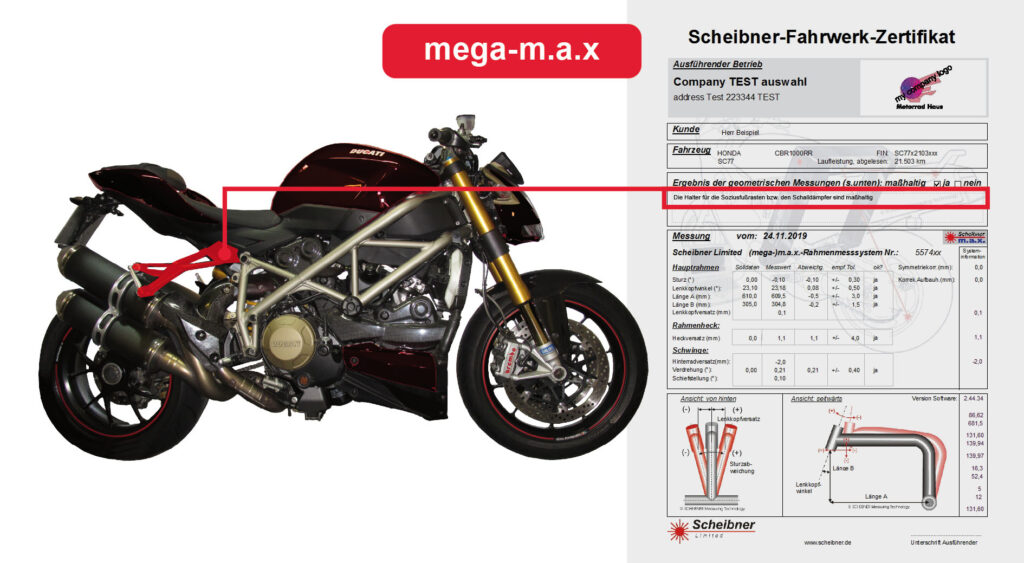

Wir arbeiten an Standards für aussagekräftige Messprotokolle wie z.B. dem Scheibner-Fahrwerk-Zertifikat

Zusammenarbeit

Wir sind der Überzeugung, dass die besten Ideen in Gemeinschaft entstehen und arbeiten mit einigen Hundert Vertragspartnern weltweit.

Verschiedene Messsysteme, passend entwickelt zur Klärung des geometrischen Zustandes von Rahmen und anderen Fahrwerksteilen z.B. nach einem Unfall

- Alle

- Motorrad

- Motorroller & MP3

- Fahrrad

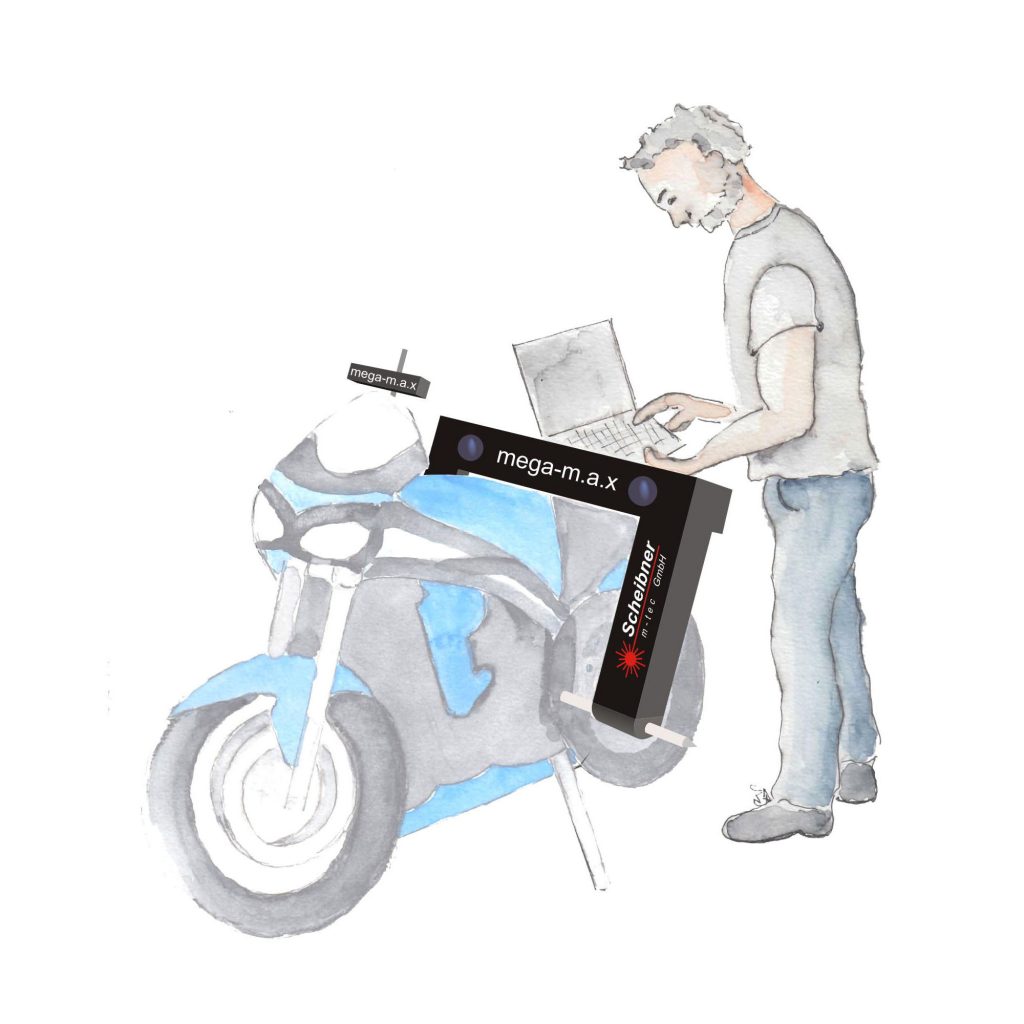

mega-m.a.x

Motorrad, Rahmen/Fahrwerk Play Video Das mega-m.a.x ist unser Standard-Messsystem für Motorräder. Es ermittelt den geometrischen Zustand des…

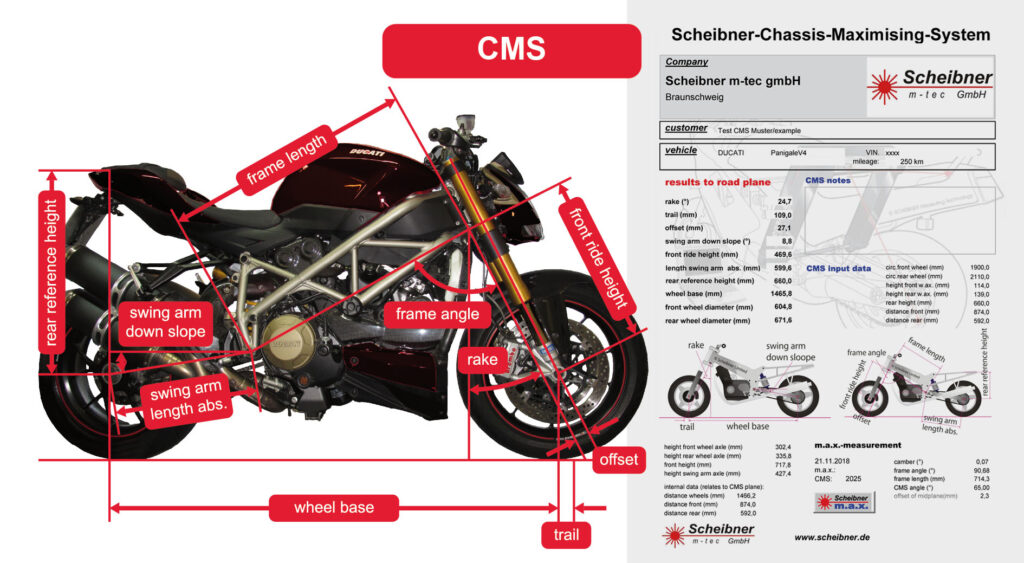

CMS

Motorrad, Rahmen/Fahrwerk, Rennsport Das CMS (Chassis-Maximizing-System) ist die optionale Erweiterung des mega-m.a.x für den Rennsport und ein ideales Werkzeug…

Feinbank-System

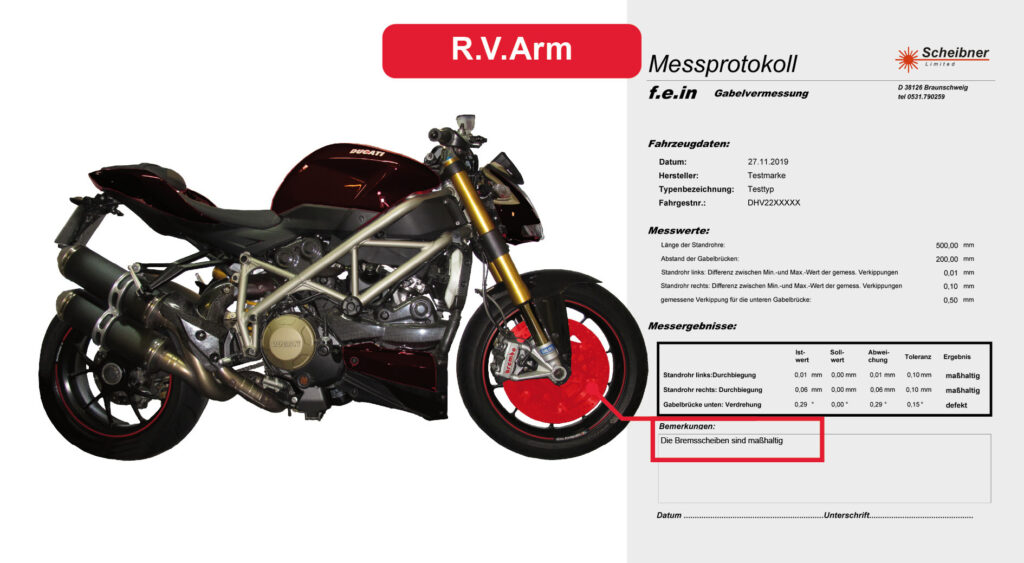

Motorrad, Vorderbau/Frontend Das Feinbank-System dient zur exakten Messung der wichtigen Fahrwerks-Komponenten des Vorderbaus (Front-End) wie Federbeine, Gabelbrücken,…

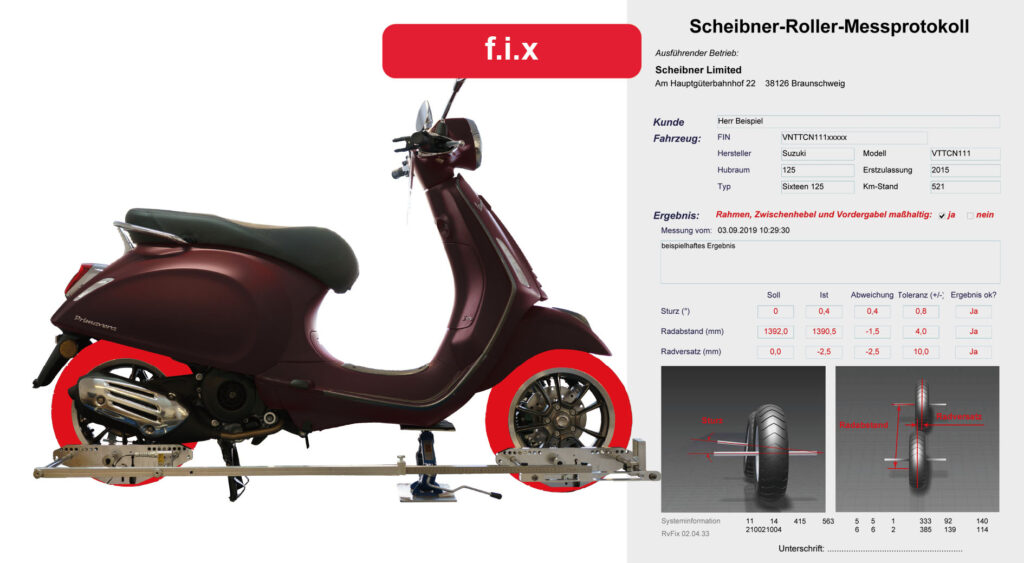

f.i.x

Motorroller & MP3 Das f.i.x-System ist unser speziell für Motorroller entwickeltes Messsystem, mit dem Sie überprüfen können,…

Fahrfix

Fahrrad Um E‐Bikes, Fahrräder und Ähnliche zu vermessen, haben wir das laser-basierte Fahrfix-System entwickelt. Es eignet sich…

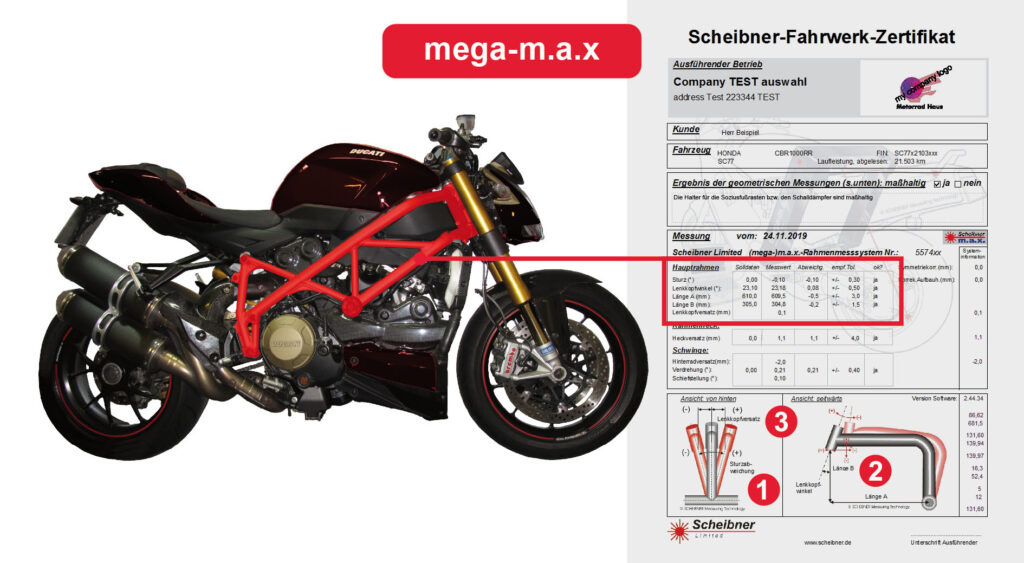

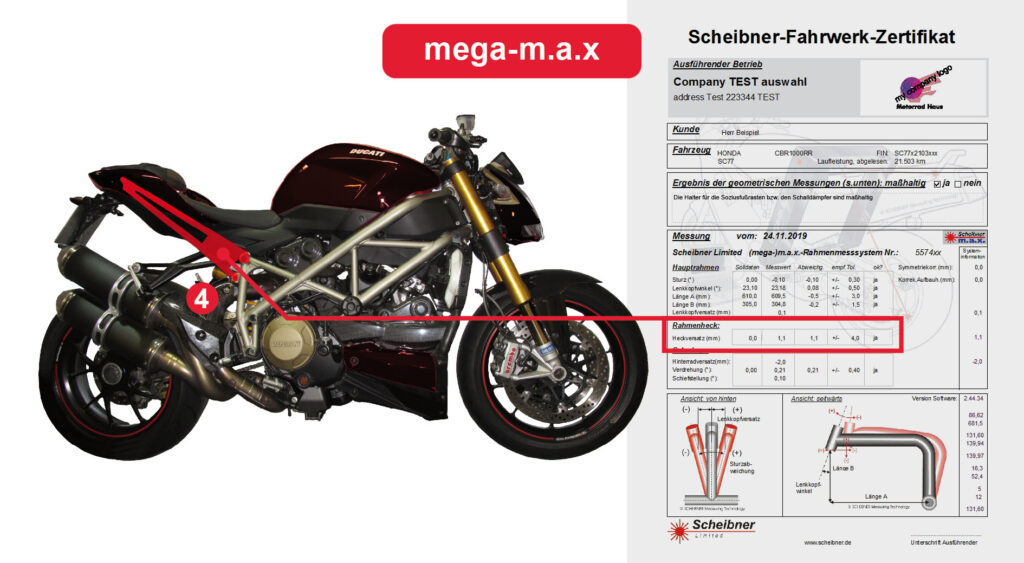

Was unsere Messsysteme messen und wie die Ergebnisse in den Messprotokollen aussehen

1 Sturzabweichung: Dieser Wert beschreibt die Winkelabweichung der Lenk(kopf)achse relativ zur Schwingenachse in einer Ansicht von hinten

2 Lenk(kopf)winkel (des Rahmens) und die Längen A und B: Diese Werte beschreiben die Winkelabweichung der Lenkachse relativ zur Schwingenachse für den Rahmen sowie die Längenabweichungen. Achtung: der Lenk(kopf)winkel (des Rahmens) ist nur bedingt mit dem Lenkkopfwinkel des kompletten Motorrades auf der Straße zu vergleichen

3 Lenkkopfversatz: Versatz der Lenkachse relativ zur Mittelebene des Rahmens. Achtung: dieser Wert dient nur zur Information für den Experten und ist für sich alleine nicht unfallrelevant

4 Versatz des Rahmenhecks: Das ist der seitliche Versatz der Mitte des Rahmenhecks zur Mitte (Mittelebene) des Rahmens

5 Hinterradversatz: Versatz des Hinterrades zur Mittelebene

6 Schwingenverdrehung: Verdrehung der Hinterachse relativ zur Schwingenachse aus der rückwärtigen Ansicht

7 Schiefstellung der Schwinge: Verdrehung der Hinterachse relativ zur Schwingenachse aus der Ansicht von oben (Probleme sind typischerweise bei Fehlern der Einstellung der Kettenspannung zu suchen)

Partner

Hier finden Sie einen unserer Partner in Ihrer Region.