The mega m.a.x is our standard measuring system for motorcycles and determines the geometric condition of the frame and other important chassis components independently of any possible damage to the front fork. It is possible to measure the swing arm, the rear frame and any definable measuring points such as fairing brackets or handlebars. The only exception is the front fork, which is measured with the f.e.in device. Due to a close cooperation with BMW motorcycle, the measurement of the innovative Duo and TeleLever suspensions is guaranteed according to BMW specifications. Yamaha also supports the mega-m.a.x system.

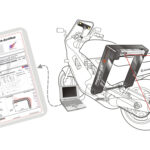

Measuring procedure The measuring bracket is picked up with the conical centering pins or one of the adapters supplied, e.g. in the bore of the swing arm axle, and supported in the rear of the vehicle with the adjustable strut. The target body is attached to the front fork with the tripod system. After connecting the PC, the vehicle type is selected from the database. Measurements are made with the handlebars turned to the left and right. Two CCD measuring cameras detect the position of the steering axis from the rotational movement of the target body or the front fork. They automatically determine the positions of two infrared-illuminated target markers, which are previously attached to the front fork in an almost arbitrary manner. A movable and rotatable laser measures the rear of the frame and the swing arm. The program shows the measurement result in comparison with the manufacturer's specifications from the database on the PC display. The Scheibner chassis certificate is ready for printing.

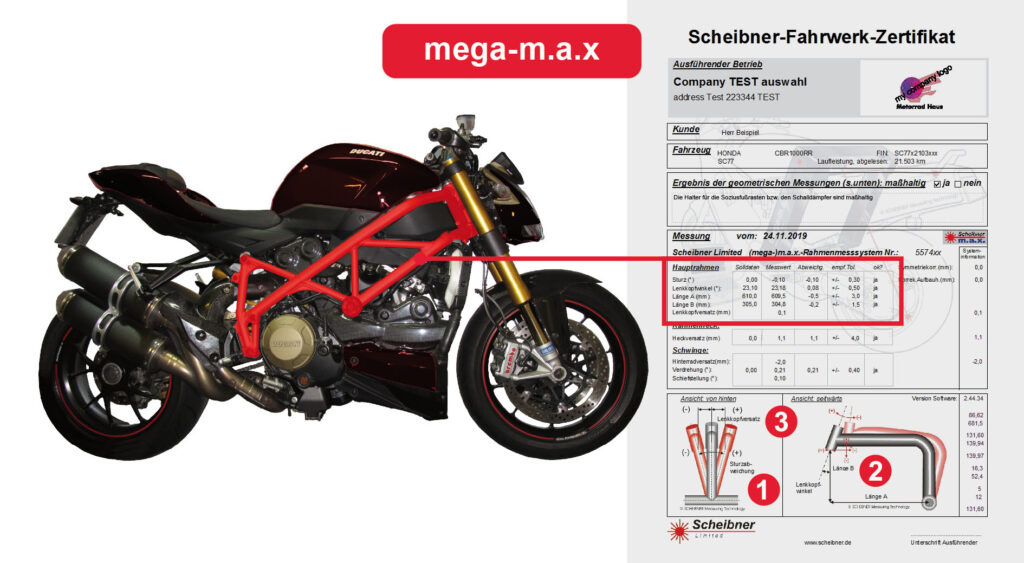

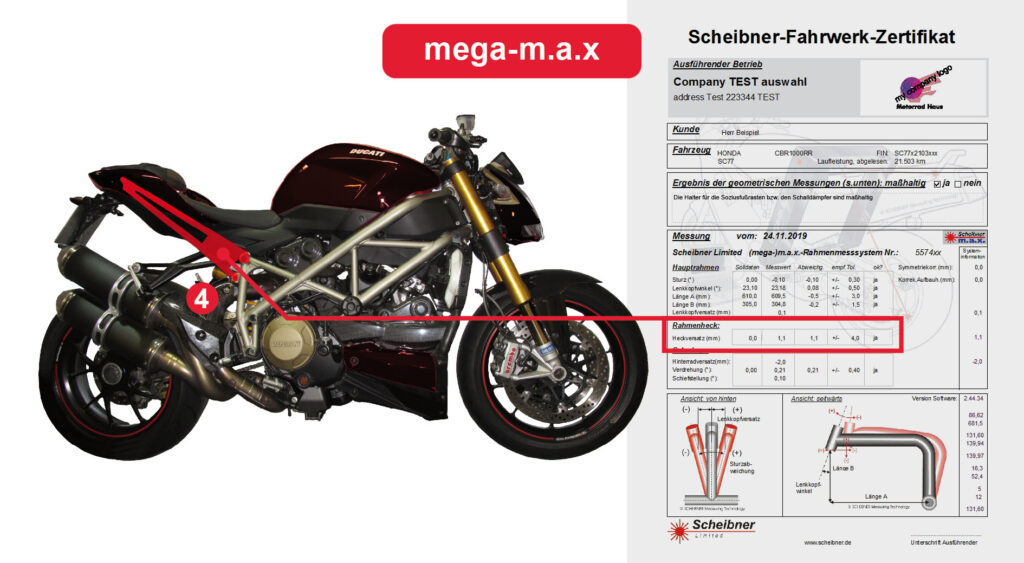

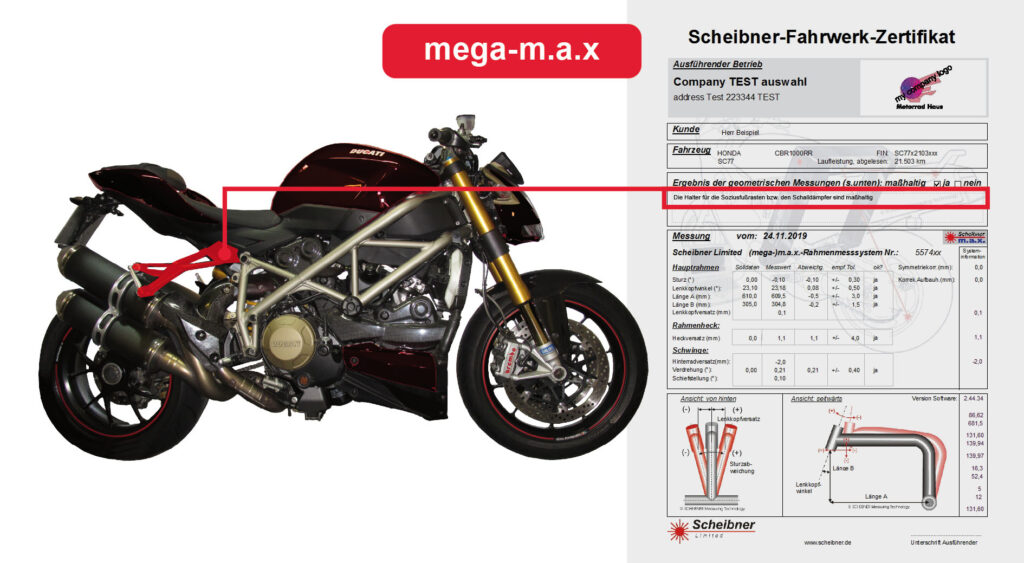

Measurement result The ›Scheibner-Chassis-Certificate‹ that you can print out on your computer using our software:

Laser ‐ optical diode power: < < 1 mW

Laser - wavelength: 650 nm

Laser - Divergence: 1 mrad

resolution for angle measurements: 0.01°

resolution for measurement of distances: 0.1 mm

Resolution electr. resolution of the integrated potentiometer: 0.25 mm

Standard equipment: mega‐m.a.x with 2 CCD‐measuring cameras, automatic computer‐controlled detection and measurement of the targets, infrared illuminated targets, RvWin software to administer the protocols and the reference data, complete list of manufacturer’s reference data, universal mounting system to fasten the targets at the front fork, presentable transportation case which fits into the boot of any compact car.

Dimensions of the case with the entire equipment: 860 x 700 x 200 mm

Weight complete: approx. 35 kg

What the mega-m.a.x measuring system measures and how the results look like in the measuring protocols

1 The camber deviation of a single-track vehicle or two-wheeler describes the position of the steering head axis relative to the swinging arm axis, with regards to distortion around the longitudinal axis of the vehicle

2 Steering head angle and length A and B provide the information displayed at the image. Please note that the steering head angle of the frame does not necessarily correspond with the rake or steering head angle of the complete motorcycle on the road such as mentioned in brochures.

3 The longitudinal axis setting is a measurement of the offset of the steering head axis relative to the midplane of the motorcycle. Please note that this value solely provides information for the expert and is, on its own, not relevant in the case of an accident.

4 The tail offset is the sideways offset of the frame rear to the midplane

5 Rear wheel offset is the sideways offset of the rear wheel to the midplane

6 Distortion of the swing arm is the distortion of the rear wheel axis relative to the swing arm axis from the rear view

7 Misalignment of the swing arm is the distortion of the rear wheel axis relative to the swing arm axis as viewed from above (problems are related in most cases to chain adjustment and not accident-related)